Digital Labels vs. Traditional Labels :In the intricate realm of product packaging, labels play a pivotal role by offering valuable insights into the product and its components. With a history spanning decades, traditional labels have been a steadfast presence. However, the advent of digital printing technology has ushered in a new era, unlocking fresh possibilities in label design and production.

Unraveling the Tapestry of Printing

Traditional Printing: A Legacy of Craftsmanship

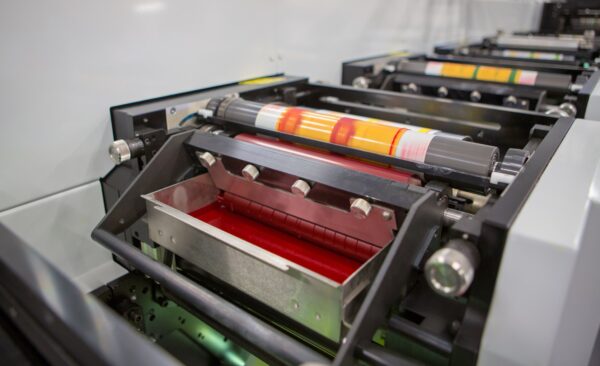

Grounded in analog methods like flexography, letterpress, or offset printing, traditional labels boast a time-tested legacy of delivering high-quality output. Yet, their setup demands substantial time and effort.

Digital Printing: A Symphony of Quick Customization

Digital labels harness the power of modern printing technology, ensuring swift and effortless printing without the need for plates or extensive setup. The game-changer lies in the realm of variable data printing, allowing unique customization for each label with information like batch numbers and expiry dates.

Quality Chronicles

Traditional Excellence

In the quality domain, traditional labels shine with high-grade output. However, factors such as ink density, paper type, and print alignment can influence the final result.

Digital Precision

Digital labels redefine precision by offering a spectrum of quality levels. Capable of intricate designs and finer details, digital printing emerges as an enticing choice for brands seeking excellence in label aesthetics.

The Clash of Durability

Traditional Stalwarts

Crafted from paper or plastic, traditional labels face susceptibility to environmental factors. Digital labels, on the other hand, embrace a variety of robust materials like vinyl and polyester, enhancing resistance to damage.

Digital Resilience

Digital labels take durability to a new level, allowing printing with UV-resistant inks to safeguard against fading and damage caused by sunlight. The choice of materials further contributes to their resilience.

Crafting Uniqueness: The Customization Odyssey

Traditional Uniformity

Traditional labels typically arrive in large quantities with identical designs, limiting customization.

Digital Prowess

Digital labels redefine the game with variable data printing, enabling each label to bear unique information. This versatility opens doors to intricate designs on materials ranging from metallic to transparent films.

The Symphony of Ease

Traditional Hurdles

Traditional label printing involves time-consuming and costly plate setups. Any design changes or alterations necessitate new plates, escalating costs and production time.

Digital Harmony

Digital label printing dances to a different tune, offering ease of customization and on-demand printing. Variable data printing ensures unique information per label, reducing waste and allowing faster turnaround times.

Unleashing Creativity: Design Freedom

Traditional Constraints

Traditional labels face limitations in design flexibility due to the constraints of printing methods. Design changes often incur high costs with the need for new printing plates.

Digital Liberation

Digital labels liberate design possibilities with flexibility in colors, patterns, and special effects. Gradients, shadows, 3D effects—the digital realm unlocks the potential for intricate and complex designs.

The Quantity Quandary

Minimum Orders in Tradition

Traditional label printing often necessitates minimum order quantities due to setup costs for printing plates. This proves disadvantageous for businesses requiring smaller quantities or frequent label changes.

Digital Freedom

Digital label printing breaks free from such constraints, allowing smaller print runs with no minimum order quantity. This flexibility caters to businesses needing smaller quantities or frequent changes.

Counting the Coins: The Cost Dilemma

Traditional Expenses

Traditional labels can be pricey, especially with custom plates or setup requirements.

Digital Economics

Digital labels, in contrast, offer cost-effectiveness for short print runs or custom orders, thanks to their quick and plate-free process. However, variables like label size, colors, and materials can influence the cost dynamics.

In the End, It’s Your Story

In the grand narrative of labels, both digital and traditional scripts have their distinct features and advantages. While traditional labels boast a legacy of high-quality output, digital labels introduce a plethora of benefits like customization, durability, and ease of use.

When standing at the crossroads between Digital and Traditional Labels, the decision is a nuanced one. It hinges on the specific needs of your product, your budget considerations, and your desired level of printing capabilities. Ultimately, the choice between digital and traditional labels is a unique journey, and selecting the option that aligns seamlessly with your requirements is paramount.